Recommended Blogs

Top 8 Use Cases of Generative AI in the Supply Chain Industry

- What is Generative AI in Supply Chain?

- 8 Use Cases of Generative AI in Supply Chain

- Opportunities and Challenges with GenAI Integration

- How Does GenAI Help with Supply Chain Planning?

- How can Tx help with Supply Chain Optimization?

- Summary

Among all industries, supply chain management might have been the slowest to adopt artificial intelligence. But in recent years, the fragility of global supply chains has caught the public eye, and it has become a necessity for the supply chain industry to dive into the sea of AI. In every country, large logistics networks are vital for manufacturers. However, they face severe challenges due to various factors, such as transportation delays, increasing network complexities, and labor stoppages.

Business leaders steadily integrate cutting-edge technology like AI into supply chain management to untangle these problematic knots. They aim to gain a competitive advantage in their industry and upscale their CX delivery level. Within the AI domain, one solution could help them upscale their key supply chain processes: “Generative AI (GenAI).”

GenAI is trending these days and gaining popularity across various business areas, such as sales, marketing, and development. It analyzes previous data to help businesses improve supply chain resiliency and operational efficiency.

What is Generative AI in Supply Chain

Generative AI in supply chain means using AI models that create new data or insights by learning from massive historical supply chain data. Its main benefits include faster decision-making, better demand forecasts, and stronger supply chain resilience.

Role of AI in Supply Chain

There are various activities that businesses manage and optimize in the supply chain with the help of AI, such as:

•Inventory Levels

•Product Quality

•Fuel-efficient Delivery Routes

AI applications include simulating human intelligence, performing complex tasks, managing security, etc. Its subfield machine learning (ML) analyzes and learns by consuming huge data sets, enabling AI systems services to outrun traditional software functionalities. This allows businesses to perform the following tasks:

• Decrypting information from videos.

• Analyzing and interpreting text and speech.

• Predicting future market trends and customer behavior.

• Assisting in decision-making in complex situations.

• Structuring insights from large data sets.

This makes it necessary for businesses to utilize tech-centered solutions like AI to manage and optimize their workflows across the supply chain. For instance, ML algorithms can optimize supply chain systems by discovering patterns and connections between datasets that go unnoticed by humans or traditional systems.

This helps businesses to accurately predict customer demands, leading to efficient and cost-effective inventory management. AI in supply chain management can analyze weather and traffic conditions to suggest faster shipping routes, reducing the risk of delays and thus improving the delivery period. It also monitors workspaces to identify poor quality controls and safety violations.

GenAI, a specific subset of AI, is trained using large datasets. When a user inputs new data, the generative AI app uses new and previous data to generate new content. Businesses can train GenAI models using supply chain data, including logistics, inventory details, and demand. GenAI can analyze organizational data to improve supply chain resilience and management.

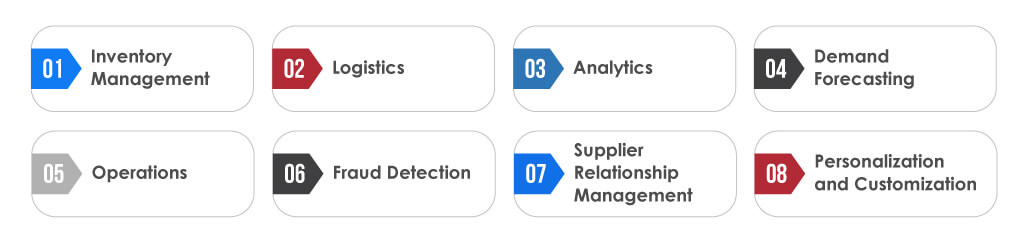

8 Use Cases of Generative AI in Supply Chain

Generative AI can tackle real-world supply chain problems by turning massive data into practical actions. These use cases show how businesses boost efficiency, cut costs, and build resilience.

Before learning about GenAI uses in the supply chain, businesses must ensure that this technology aligns with their objectives and delivers benefits accordingly. Now, let’s take a quick look at some use cases of generative AI in supply chain management:

Inventory Management

GenAI models can assist in optimizing inventory management. Businesses can train these models using data about stock levels, warehouse capacity, and manufacturing date/time. It will use this information to optimize inventory processes, including recommendations about restocking or reducing stock. This would allow businesses to save expenses on excess storage.

Logistics

Logistics disruptions are a common problem businesses face in supply chain management. Traffic accidents, bad weather conditions, and labor shortages are some of the events making it difficult to maintain shipping schedules.

Training GenAI models using past weather patterns, traffic maps, fuel prices, and labor stats can help businesses identify optimal travel routes. It would also suggest alternate routes if there’s an upcoming disruption. This will allow businesses to keep shipments on schedule and improve CX and service.

Analytics

GenAI can run simulations and multiple scenarios to assess risks and draft a report. It can also assist in analyzing and pinpointing the key problematic areas in supply chain processes and recommending the appropriate measures to resolve them.

Demand Forecasting

Supply chain operations are unpredictable. They depend on consumer buying behavior, demand for the product or service, and market prices. Enterprises can train their GenAI models on past sales data, customer behavior, market trends, and other elements to predict future supply-and-demand scenarios and optimize their demand forecasting accuracy. This would allow them to mitigate supply chain disruption and prevent stocking issues.

Operations

Implementing new technologies and fluctuating user demands can cause operational challenges. GenAI can assist businesses in tackling those challenges and improving supply chain operational efficiency. It can assess performance and manufacturing speed, find areas for improvement, and suggest ways to optimize them.

Fraud Detection

One of the primary benefits of GenAI models is that they can be trained and fine-tuned to predict the possibilities of fraud occurrences. GenAI can identify complex patterns by analyzing financial data and can aid in detecting fraudulent activities.

Businesses can use GANs (generative adversarial networks) to create fraudulent transactions using generator networks and a discriminator to identify them. This whole system helps improve fraud detection capabilities and will aid in strengthening security protocols in supply chain management.

Supplier Relationship Management

GenAI can assist in identifying reliable partners by analyzing markets and suppliers. It helps establish stronger relationships with suppliers, ensuring a high-quality and consistent supply of services/products. It would help businesses negotiate better, secure favorable contracts, and access competitive pricing. This can reduce procurement costs and optimize supply chain efficiency.

Personalization and Customization

Industries like electronics and fashion require high customization. GenAI can help create personalized and customized products according to user preferences while adhering to production and supply constraints.

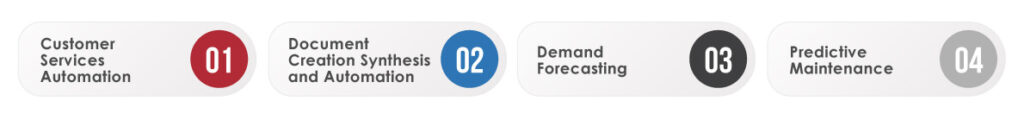

Opportunities and Challenges with GenAI Implementation

• GenAI offers countless applications to optimize supply chain operations, which include.

• Customer services automation.

• Document creation synthesis and automation.

• Demand forecasting.

• Predictive maintenance.

It can identify patterns from existing data and insights to help businesses manage their supply chain operations. Despite its potential benefits and opportunities, there are some challenges in supply chain management, including data privacy, security, and access controls for AI tools within the business IT ecosystem. These challenges urge enterprises to develop GenAI solutions in-house or by partnering with vendors, and they miss opportunities and toolkits offered by open models.

The supply chain industry is now partially ready to adapt and integrate GenAI into its operations. However, it will gain momentum later with sufficient support and quality leadership. According to Gartner, 80% of the global supply chain market is still not incorporated into digital business models. This gap will continue to affect supply chain performance goals until sufficient tech investments are synced with decision models.

AI and ML are among the top 10 trends in supply chain management. However, the delay in adopting GenAI could be due to the complexities of supply chains and the need for business-specific model training.

How Does GenAI Help with Supply Chain Planning?

Generative AI helps supply chain teams plan better by turning historical and real-time data into practical actions. It builds realistic scenarios, spots hidden risks, and recommends adjustments before problems hit.

Keyways GenAI supports planning

- Makes a lot of different situations for demand and supply so that teams can plan ahead.

- Looks at supplier performance, lead times, and costs to make procurement planning better.

- It can predict when production will slow down and offer solutions to spread out the work among other facilities.

- Models seasonal trends and sudden changes in the market to help with inventory planning.

How can Tx help with Supply Chain Optimization?

Caution is a primary factor when dealing with tech, especially AI-based. GenAI models are still evolving, so one must have sufficient measures to tackle AI-related concerns. Incorrect data, imperfect outputs, and AI hallucinations are current concerns that can prevent the effective use of AI in the supply chain. Tx is a leading quality assurance provider offering comprehensive GenAI testing services. We can assist you in tacking generative AI in supply chain implementation challenges by offering the following:

• Dedicated AI testing team possessing in-depth knowledge of GenAI algorithms and their applications in the supply chain.

• A comprehensive testing approach tailored to generative AI models to validate their accuracy and reliability.

• Implementing cutting-edge testing tools and frameworks, including our in-house AI-based accelerators (Tx-Automate and Tx-SmarTest) to enhance the effectiveness of generative AI testing.

• Adherence to data privacy and compliance with supply chain industry regulations to securely handle information during testing.

Summary

Generative AI is changing how supply chains are managed by using it in real life for things like predictive maintenance, fraud detection, and demand forecasting. These examples of generative AI in the supply chain assist lower costs, make the system more resilient, and make the customer experience better. There are still problems to solve, such data privacy and model accuracy, but the chance to change is evident.

FAQs

Generative AI in the supply chain uses complex algorithms to learn from massive amounts of supply chain data and provide new predictions and insights.

Generative AI looks at big sets of data on logistics, inventory, and demand to come up with insights that help with planning and making decisions. It helps find the best routes, predict demand, spot fraud, and automate everyday operations all along the supply chain.

Generative AI models simulate various risk scenarios and predict disruptions before they happen. It allows businesses to create flexible contingency plans, reduce downtime, and quickly adapt to unexpected changes like supplier delays or market shifts.

Generative AI makes supply chains proactive instead than reactive, which transforms them. It makes predictions more accurate, takes care of tough decisions, and finds hidden patterns, all of which save money and make customers happier.

Generative AI helps supply chains get back on track after problems by predicting hazards before they happen. It runs simulations of possible difficulties, like as delays from suppliers or strikes by transportation workers, so that companies can make backup plans and act more quickly when things go wrong.

Discover more